Compact ACQPC based technical data

End-Line Acquisition System with Workstation

This PC-based system has been designed and produced to meet the

needs for

performing Quality Control of an End-Line product.

The whole system is contained in an industrial workstation and is supported

by a TFT 10,5" graphic display (equal 14" CRT).

Compact ACQPC based technical data

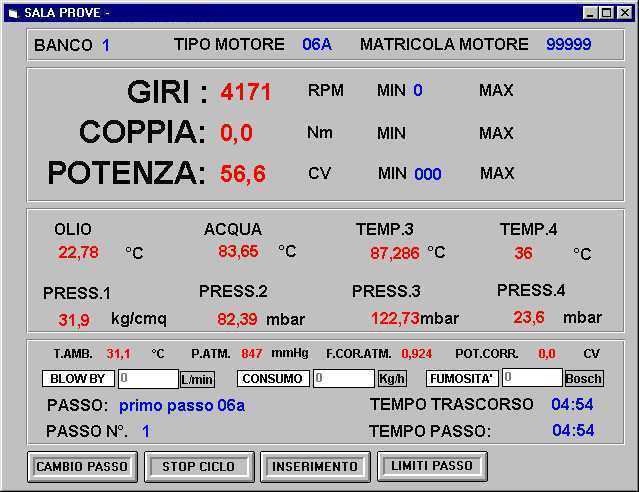

In the field of endothermic motors, the Compact-ACQPC system is managed

by

" TECNOWIN ", a fully configurable software developed in Windows

that allows

the interfacing with a bar code optic reader that automatically recognizes

the types

of motors being tested and consequently selects the corresponding pre-set

automatic

cycles to carry out.

In each step of the cycles, minimum and maximum limits of acceptability

can be

entered for every parameter acquired. If these limits are not observed,

the system

will not perform the next step.

You can manually or automatically insert the results of tests performed

with other

instruments, including consumption test, blow-by, grade of smoke, etc.

The time for each step is also memorized, in addition to the total

time of the test on the motor.

These will then be printed in the 80-column test certificate, specifying

all parameters

recorded at the end of the step with relative limits. All these

procedures guarantee the

manufacturer that the product has been tested and that it complies

with the stated characteristics.

The Standard Base System can acquire the following channels:

Because we produce the entire system, hardware and software alike, we

can design

customized systems according to the client's needs.

The Compact ACQPC system can be installed

with the following TECNO EL software packages:

HERCULES - Management program for endothermic motor

test rooms

TECNOWIN - Management

program for end-line motor test rooms

ELEKTRO - Management

program for electric motor test rooms

CUBE4 - Processing program for acquired data

| INFORMATION | PRODUCTION | NEWS! | OCCASIONS! | SERVICES |

| HOME PAGE |