Test room design

Electric motors

Tecno EL not only produces equipment and software, but can also

design and build a turnkey motor test rooms to meet every requirement.

Our Technical Department will see to all stages of the design, including:

-

Sound-proof cabin and masonry work

-

Hydraulic system

-

Mechanics

-

Acquisition electronics

-

Electrical system and primary and secondary lighting system inside

and outside the room

-

Ventilation system

-

Control of cooling tower, cooling pumps, heat exchangers

-

Accessories inside and outside the test room

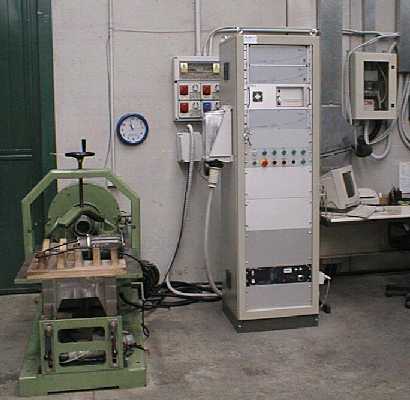

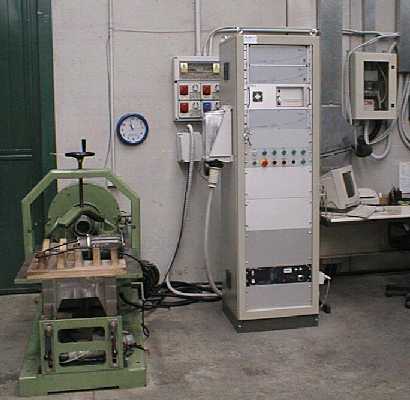

The image above shows a typical example of a turnkey electric

motor test stand designed and built by Tecno EL.

The electronic equipment, including:

-

Interfaces

-

PC

-

Resistance meter

-

V.I.W

-

Brake feeder

-

and others….

are housed in a rack cabinet.

On the desk under the window in the room or in the immediate

vicinity sit the following:

-

Monitor, Keyboard and mouse

-

Printer

-

Console for remote controls

All controls for equipment outside and inside the room,including

-

Power line for feeding motor tested

-

Single-phase to three-phase switching

-

Voltage converter with manual and automatic controls

-

50/60 Hz frequency converter with manual and automatic controls

-

Bank of 8 capacitors for tests on single-phase motors

-

Primary and secondary lighting system

-

Control of primary and secondary electrical utilities

-

Brake water cooling pumps

-

Cooling tower circulation pumps

-

Thermoregulation system

are housed in a second cabinet containing signal lamps and control buttons

to make for an excellent user interface. The electrical system inside

the room and the wiring layout are carried out in conformity with the

most

recent EEC standards, and are the result of our 15-year experience

in the field.

Runners and ducts are built in metal, and are aesthetically pleasing

and

functional at the same time.The hydraulic system has been designed

with care

and the pipes are positioned so that they won't interfere with work.

All Elektro systems can alternately control 2 simple test stands (eddy current

brake only)

or TANDEM stands, since the software takes care of switching all the

controls.

Working together with the companies mentioned above, Tecno EL

can directly supply

brakes and the related control instruments, as well as perform wiring

and direct interfacing

with the acquisition equipment.

To complete the test room, la Tecno EL can also supply a 50/60

Hz

frequency converter and voltage converter, which we can see positioned

next to one of our electrical panels for a client who chose Elektro

as an

instrument for its tests (see photo).

Both are furnished according to specific requirements and interfaced

with

electrical panels by our qualified personnel.

These two devices, in addition to the control panel, can also be provided

for updating or expanding a pre-existing test stand.

Pictured below is example of a cooling tower that Tecno EL supplies

with the motor test room.

Because they understand the maximum power of the motors being tested,

our technicians

can calculate the size of the tower, pumps and pipes needed to build

the entire system.

For the cooling system to operate efficiently, Tecno EL offers the

following accessories:

-

unit of solenoid valves for controlling water

-

water pump unit, comprising:

-

tank filling pump

-

motor water pump

-

cooling tower water circulation pump

-

water treatment system, comprising:

-

dispensing pump

-

product management box

-

container of chemical product for water treatment

after analysis of water used for determining correct quantity and

type of product to use.

In addition to the supply, Tecno El can naturally perform a turnkey installation.

| INFORMATION |

PRODUCTION |

NEWS! |

OCCASIONS! |

SERVICES |

| HOME PAGE |